The methods we use correspond to standards such as IEEE 299 and ASTM D4935. We also make test benches to measure the required characteristics or performance of your products.

Our Global-N ESPEC chamber provides all the required temperature and humidity testing capabilities for clients to be able to check the quality and reliability of ever increasingly sophisticated electronics and other products.

The Global-N chambers meet the standards set by JEDEC and the IEC as well as other international testing standards.

The CompactDAQ system is a portable platform allowing data recording in a wide variety of working environments, be it aboard vehicles or in a research laboratory. The breadth of bus, chassis, controller and I/O conditioning options, together will the customizable nature of LabVIEW software provide the best solution to meet the requirements of a large number of applications.

The NI CompactRIO system combines open embedded architecture with a compact size, is extremely robust, includes hot-swappable industrial I/O modules, and is powered by the NI LabVIEW reconfigurable I/O (RIO) architecture.

The Ni 1778 smart camera is able to capture CCD Sony monochromatic images with a resolution of 2448 x 2050 (5 MP) at 15 fps. It is one of the high performing NI smart cameras using the powerful Atom 7.6 Ghz processors for industrial inspection applications.

Its IP67 casing, M12 connectors and lens protection guarantee a waterproof (up to 1m) and dustproof seal.

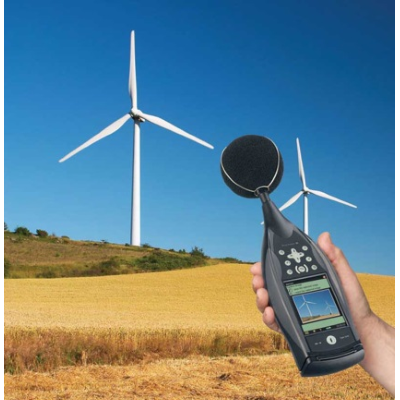

This sound level meter has all it needs to carry out precise class 1 measurements in environmental and industrial applications.

Two measurement channels enable sound intensity measurements meeting IEC 61043s standards.

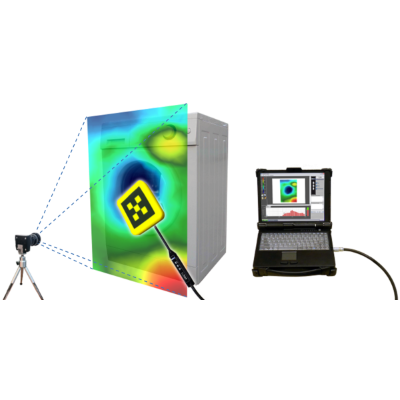

The I-Track system is a powerful tool used to map sound intensity in a fast, east and precise way. The result is high definition sound mapping and an automatic calculation of sound power in just a few minutes.

HandySCAN 700™

This new generation of HandySCAN 3DTM handheld scanners is optimized specifically for product development and engineering professionals looking for the most effective and reliable way to acquire 3D measurements of physical objects.

INDUSTRIAL COMBUSTION ANALYSER TESTO 330-2G-LL KIT 1

State of the art equipment for taking important measurements in fuel facilities. Additional accessories can also used to measure temperature differential and look for gas leaks.

CO readings at up to 30 00 ppm.

Approved by TÜV according to EN 50379, parts 1-3 standards

This high-speed camera is the ideal tool for many applications and contains high internal memory capability and advanced triggering capability. The MS55K camera captures monochromatic images in a range of 25 to 3000 fps.

The Fluke Ti300 thermal camera has a LaserSharp® built-in automatic focus system. Its sturdy frame guarantees longevity in all environments. Fluke IR-Fusion® patented technology, with its AutoBlend™ mode provide rapid detection and communication of problems.

Specifically designed for those wanting to optimise energy consumption, the three-phase Fluke 1730 Electrical Energy Logger offers a new easy way to identify electrical energy loss sources. By studying the energy consumption of facilities, the machine allows clients to identify potential energy savings and, thanks to easy-to-read data, implement appropriate actions.

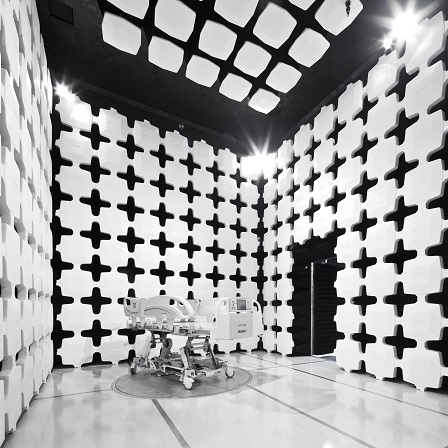

Electromagnetic Compatibility (EMC) and Electrical Safety Laboratory

Our infrastructures in electromagnetic compatibility and electrical safety are fully equipped and unique in eastern Quebec. These infrastructures can accommodate all kinds of electrical appliances (single-phase, three-phase, CC, battery-run and all tests are carried out to international requirements (CSA, UL, FCC, CE, IEC, …).

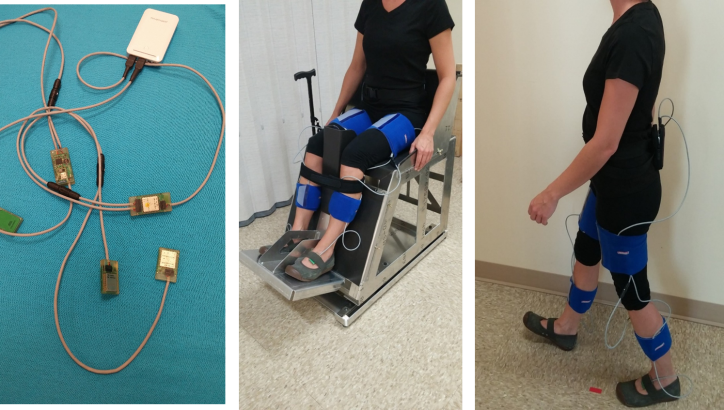

The biomechanics laboratory is equipped with a motion sensor system using active sensors (Optotrak Certus) which can reach a resolution of 1 mm. Coupled with a force plate on the ground, it allows the analysis of movement dynamics. Also available is a variety of motion capture systems per inertial unit (VectorNav, XSens, Shimmer).

The laboratory is also equipped with physiological measuring devices such as wireless electromyograms (Delsys Trigno), wireless pulse oximetry (Nonin WristOx2) and a non-invasive system for continuous measurement of blood pressure (Nexfin Bmeye).