APPLICATION OF PHYSICS TECHNOLOGIES IN THE DEVELOPMENT OF INDUSTRIAL PRODUCTS AND PROCESSES

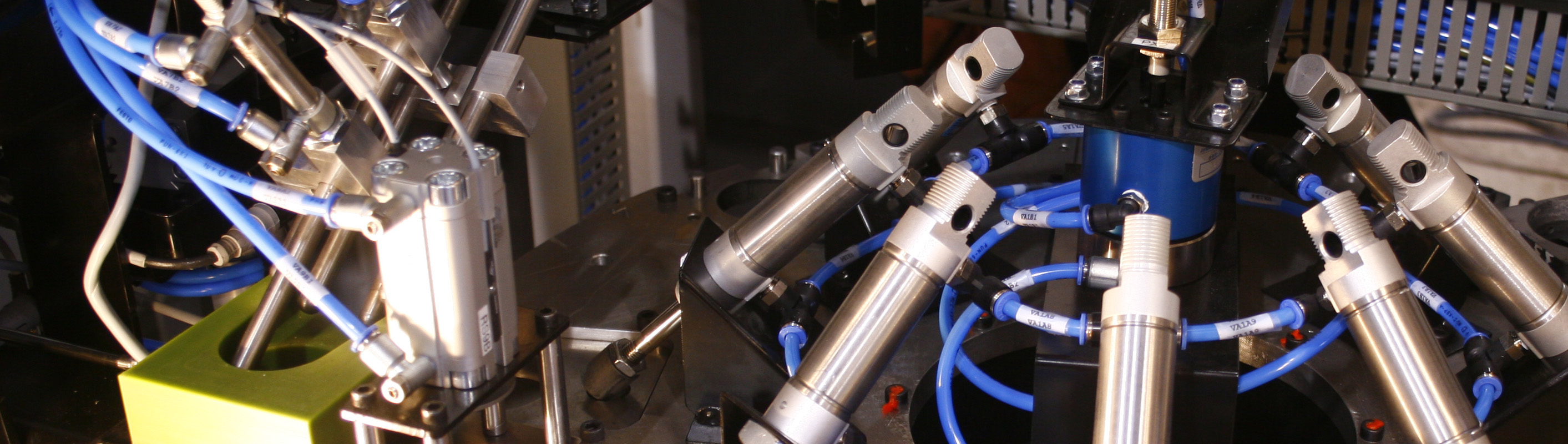

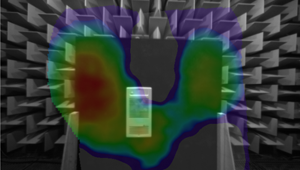

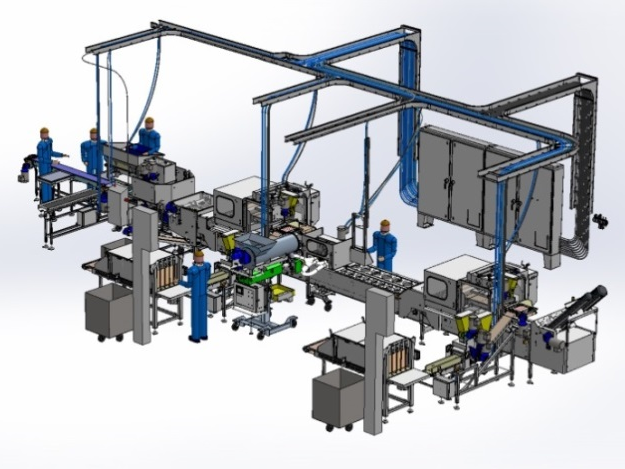

Our mechanical team is called upon to intervene in and solve specific engineering problems, using multidisciplinary knowledge and expertise taken from the fields of mechanical engineering (mechatronics, thermodynamics, fluid dynamics, etc.) and physics engineering (vibrations, acoustics, optics-photonics, etc.).

(418) 856-4350, ext. 135

(418) 856-4350, ext. 135